- Energy saving

- Hydronic heating

- Insights

- Radiators

- Improve efficiency

The role of hydronic balancing and radiator valves in energy saving

What is hydronic balancing?

Hydronic balancing ensures that the right amount of hot water flows through every terminal unit (radiators, fan coils, etc.) by creating the least amount of friction taking into account the resistance of the distribution network. It’s about making sure that the heating system can operate under all conditions it was designed for and effectively preventing over- or undersupply. Based on a room-per-room calculation of the heat load and the design parameters specific to the heat generator, the volume flow of hot water is set for each room. This requires a good understanding of the heating system since the resistance is created in the thermostatic radiator valves that are placed strategically within the network.

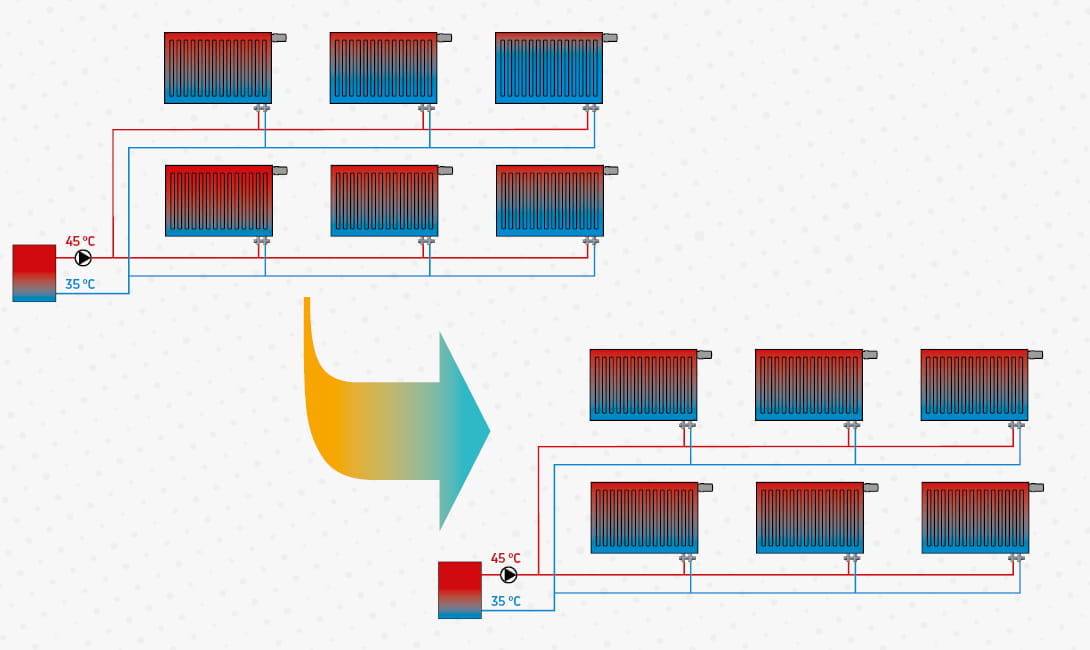

Optimising the distribution of water in a heating system by balancing the need for pressure with the resistance in the system ensures that there is an even heat distribution in the pipe network. If the radiator farthest from the heat source receives its desired flow, measured in resistance, the units will also get their required flow. When this is done, the pump can be set according to the required pump pressure.

If the heating system is not hydronically balanced, radiators close to the pump will be warmer than required, while radiators far from the pump will be cooler. The oversupply of hot water to the radiators closest to the heat generator prevents the following radiators from being correctly supplied when necessary, as a result of which the required room temperature won’t be reached.

Hydronic balancing with thermostatic radiator valves

In the past, the heating water circulation pump was often dimensioned larger than necessary or the flow temperatures were set higher than they needed to be in an effort to ensure a sufficient flow of hot water to the radiator farthest from the heat source. However, both actions cause unnecessary energy losses. Hydronic balancing helps to create an efficient heating system and can be done by means of adjustable thermostatic radiator valves. These limit the mass flow to avoid an unbalanced water distribution.

The role of adjustable thermostatic radiator valves

A thermostatic control unit consists of a thermostatic head and an adjustable valve insert. While the thermostatic head is visible and helps to control the room temperature, the valve insert is hidden and controls the actual flow of water to the radiator. The interaction between the thermostatic head and radiator valves turns the heating system into a variable flow system that is able to respond to fluctuating outdoor temperatures and constantly changing indoor heating demands to maintain the desired room temperature. They ensure stable pressure conditions and guarantee ideal working conditions for the heating system.

Dynamic hydronic balancing

In general, either static balancing or dynamic balancing is applied. Static balancing is only used for full load conditions and might lead to an unbalanced system in case of partial load operation. To optimise the energy-saving potential of a radiator system, however, dynamic hydronic balancing is recommended. This balancing solution allows for the differential pressure on the radiators to be kept at a constant level throughout the building under all load conditions. By using dynamic balancing valves or pressure-independent control valves the mass flows are maintained at all times, even under partial load or changing load conditions.

Since the return temperature can be lower – below 55°C for optimal efficiency of a condensing boiler – and the pump consumes less electricity as it can be set to a lower speed, dynamic hydronic balancing is able to optimise the heating system’s efficiency and allows for significant energy savings throughout the year regardless of changing heating requirements or user behaviour.

Hydronic balancing in low temperature heating systems

While hydronic balancing is important for all radiator systems, it’s especially so in low temperature heating systems. Hydronic balancing ensures the system is set to the temperatures that suit the energy source the best. In case of a condensing boiler, lower return temperatures allow the boiler to work as efficiently as possible. If a heat pump is installed, it’s possible to create a large impact on the COP of the heat pump by setting the system to low temperatures with correct flow and return temperatures. The heat pump then will consume less energy to supply the right amount of energy to the building.

How much energy can hydronic balancing help to save?

An in-depth study performed at the ITG in Dresden(2) showed that in existing multi-family houses that have radiator heating, thermal energy consumption is typically reduced by 7-16 kWh/m2. It’s no surprise that the highest savings are realised with dynamic hydronic balancing. The same study showed that if dynamic balancing were implemented in all hotels in Germany, this could save up to 24,2 m kWh/year, which amounts to 7,480 tonnes of CO2.

Moreover, in its folder on system balancing for technical building systems(3), the European Building Automation Controls Association (eu.bac) mentions a study at the Technological University of Dublin that showed that the total potential savings from optimizing hydronic distribution in domestic EU heating systems amount to 22.6 Mtoe. 53% of this would come from a reduction in pumping power and the other 47% from a reduction in heat energy consumed by the systems.

Find the best radiator valves for optimal hydronic balancing

Sources:

(1) Results for a multi-family reference case in the study ‘Hydronic balancing and control – how to overcome the global challenge of reducing energy use in multifamily housing’ by Osojnik et al. https://www.eceee.org/library/conference_proceedings/eceee_Summer_Studies/2017/5-buildings-and-construction-technologies-and-systems/hydronic-balancing-and-control-8211-how-to-overcome-the-global-challenge-of-reducing-energy-use-in-multifamily-housing/2017/5-235-17_Osojnik.pdf/

(2) 2019 research report entitled “Potential Energy Savings and Economic Evaluation of Hydronic Balancing in Technical Building Systems” https://files.danfoss.com/download/CorporateCommunication/BuildingEfficiency/Potential-Energy-Savings-and-Economic-Evaluation-of-Hydronic-Balancing-in-Technical-Building-Systems.pdf

(3) System Balancing for Technical Building Systems: A great opportunity for Energy Savings and Comfort. https://eubac.org/wp-content/uploads/2021/03/20210322_eubac_System_Balancing_for_TBS.pdf